AITiO₂ST™

Half of the world TiO₂ market products are produced by sulfate process. There are more than fifty sulfate TiO₂ production plants all over the world. Most of them are located in Europe, Asia and South America. Those TiO₂ sulfuric plants have problems with disposal of liquid and solid wastes, air emissions or carbon footprint, to a greater or lesser extent. Due to the fact, that 70 tons of waste requiring disposal are produced for one ton of produced titanium dioxide, several different practices for the utilization of hydrolysis acid and acid wastes from the sulfate process exist in the world: one of the methods is a potential source of large-scale environmental disasters, others excessively increase high capital and operating costs or are not environmentally friendly and cost-effective.

EXISTING PRACTICES FOR THE ULITIZATION OF HYDROLYSIS ACID AND ACID WASTES FROM THE SULFATE PROCESS:

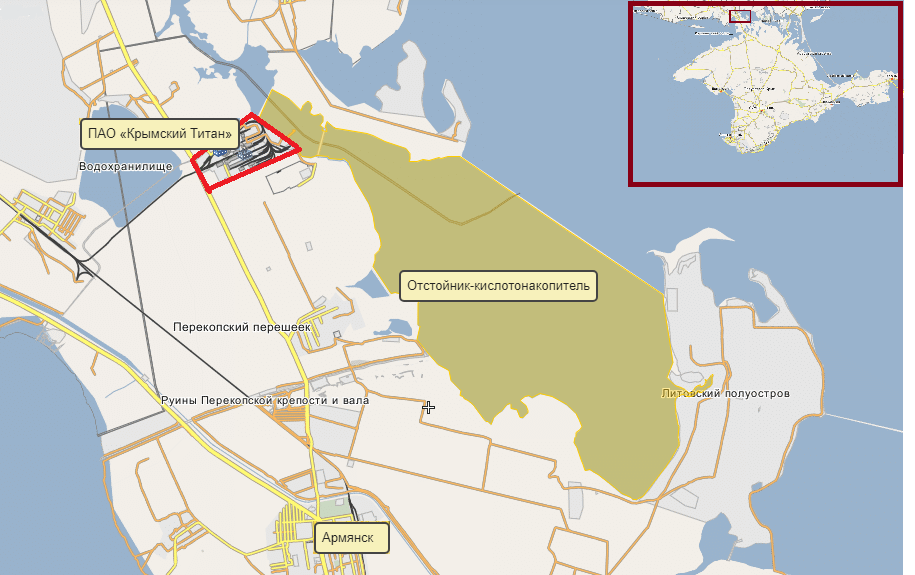

DISCHARGE INTO WATER

The acid lake of Crimea Titan, AR Crimea, Ukraine. Map source: https://www.liga.net/economics/opinion/proklyatie-titana-katastrofa-sovetskogo-razliva

Discharge into water

Discharge of weak sulfuric acid into water:

oceans, seas, rivers, special lakes, etc.

Drawbacks:

- Extremely negative environmental impact;

- Potential source of large-scale environmental disasters;

- Currently prohibited in most countries of the world, including China; in the last decade, China’s government has introduced extremely stringent environmental restrictions and has banned construction of new sulfate titanium dioxide production plants.

Evaporation of weak acid

Evaporation of weak acid containing 25% to 68% of H₂SO₄ and its further use for various needs, for example, in the production of mineral fertilizers, or strengthening of the acid from 68% to 94% with concentrated sulfuric acid or oleum and its further reutilization for ilmenite decomposition. This method is unacceptable for acidic wastes with low concentration of H₂SO₄, due to excessively high capital and operating costs.

Drawbacks:

- Increased production cost (evaporated sulfuric acid is about 4-5 times more expensive than fresh sulfuric acid).

- Impossibility for most manufacturers to evaporate the entire volume of hydrolysis acid due to the disbalance of flows;

and an attempt to solve the problem by evaporating to a higher concentration leads to a significant increase in capital costs and even greater increase in production costs.

- Generation of iron sulfate monohydrate as a waste with high content of free sulfuric acid, which requires disposal.

EVAPORATION

Source: https://www.ecoplanning.fi/Documents/KBR_Ecoplanning_Brochure_Final.pdf

NEUTRALIZATION

Sourse: https://www.ilgiunco.net/2017/10/11/bartolina-bellettini-borghi-pensa-di-essere-ancora-sindaco-anche-il-comitato-contrattacca/

Neutralization

Neutralization of weak sulfuric acid with limestone and/or lime milk and, as a result, formation of gypsum.

Drawbacks:

- When the entire volume of hydrolysis acid formed is neutralized, a huge amount of gypsum is produced as a solid waste (~ 4-5 tons per 1 ton of titanium dioxide), requiring further utilization. Land disposal of such amounts of waste is prohibited in some countries, for example, in the European Union, Directive 92/112/ EEC (Article 7) limits the amount of gypsum waste to be discharged at the level not exceeding 0.8 tons per 1 ton of titanium dioxide.

- Large areas are required for the disposal of solid wastes (gypsum).

- Use of cheaper limestone increases carbon footprint due to CO₂ emissions as a result of neutralization reaction, and the use of more expensive lime milk significantly increases the cost of the process.

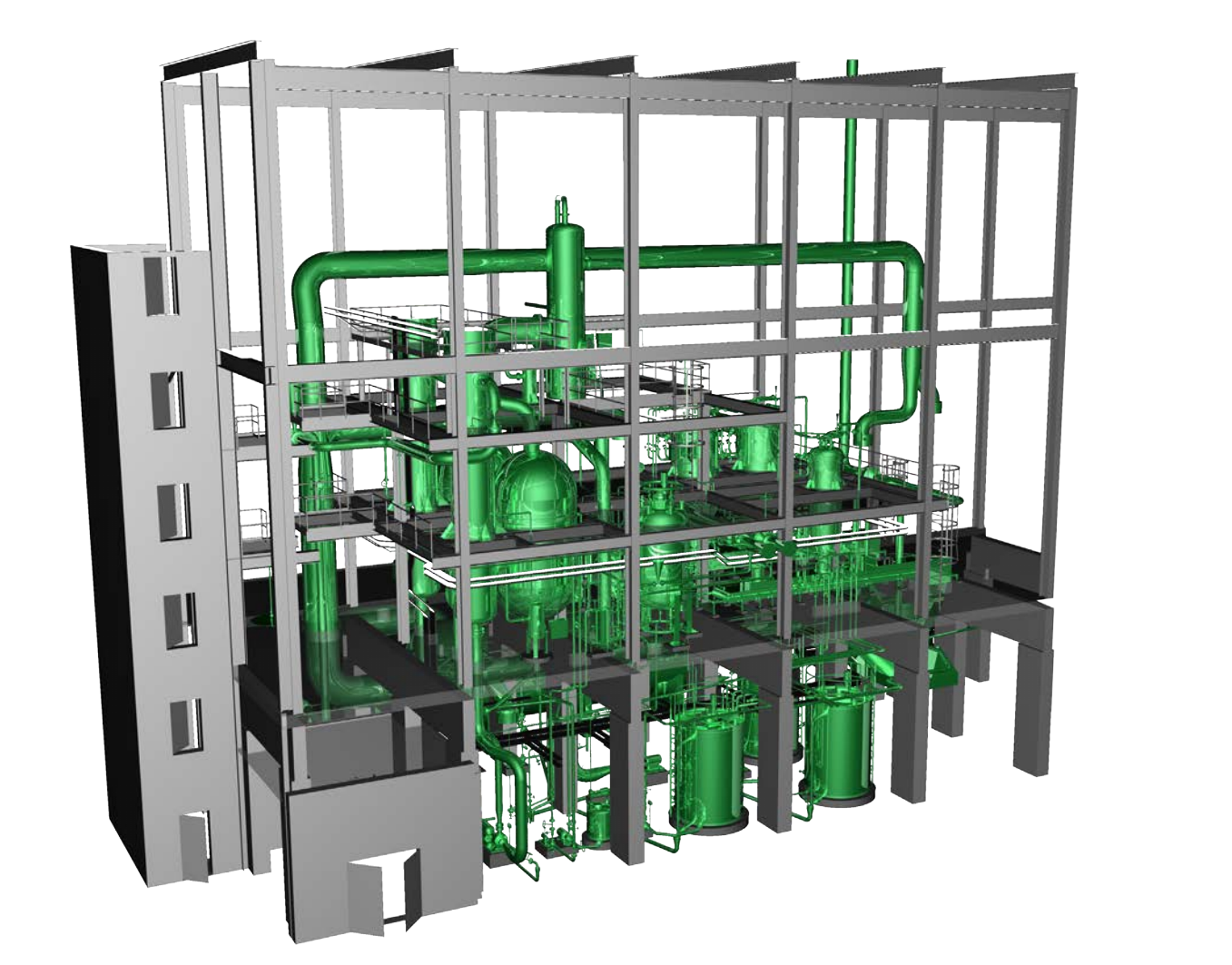

ENVIRONMENTAL-FRIENDLY&COST-EFFECTIVE SOLUTION FOR SULFATE TiO₂ PRODUCTION PLANTS DOES EXIST!

– New Prospects for the Development of Sulfate TiO₂ Technology

Using AITiO₂ST™ technology, new sulfate plants could be launched, or the sulfate production process at an old plant could be partly modernized/upgraded, whereas a variety of wastes would be transformed to saleables with high added value. As a result, productivity and economic efficiency will rise significantly.

ADVANTAGES OF AITiO₂ST™ TECHNOLOGY

Economic

Efficiency

Creating a portfolio of

high value-added products makes production flexible to changing markets, thus, leading to significant increase in economic numbers of production in comparison with conventional sulfate and chloride technologies.

Non-waste

production

‘Green’ technology has minimal environmental impact: zero liquid wastes,

almost no solid wastes, following the best European practices for air emissions, significant reduction of CO₂ emissions.

Energy

Efficiency

Reduction of fresh water, natural gas,

power and steam consumption leads to maximum energy efficiency.

Automation

The technology provides implementation of ‘Smart Factory’ approach, taking into account recent advances in the field of automation and production management in keeping with Industry 4.0 concept.

REQUEST A BROCHURE TO BE MAILED TO YOU

GET A BROCHURE WITH FURTHER DETAILS FOR FREE

The brochure will be sent to your email address.

MEET OUR TEAM

OUR TEAM

We have built the team of professionals to work on Advanced Innovative TiO₂ Sulfate Technology:

Viktor

Troshchylo

Technical Director

Andriy

Gonchar

Director

Mykola

Medvid

Consultant /

Senior Process Engineer

Oleksandr Chukhmanov

Chief Chemist

COLLABORATION

ASSOCIATED AND MAIN PARTNERS:

COLLABORATION